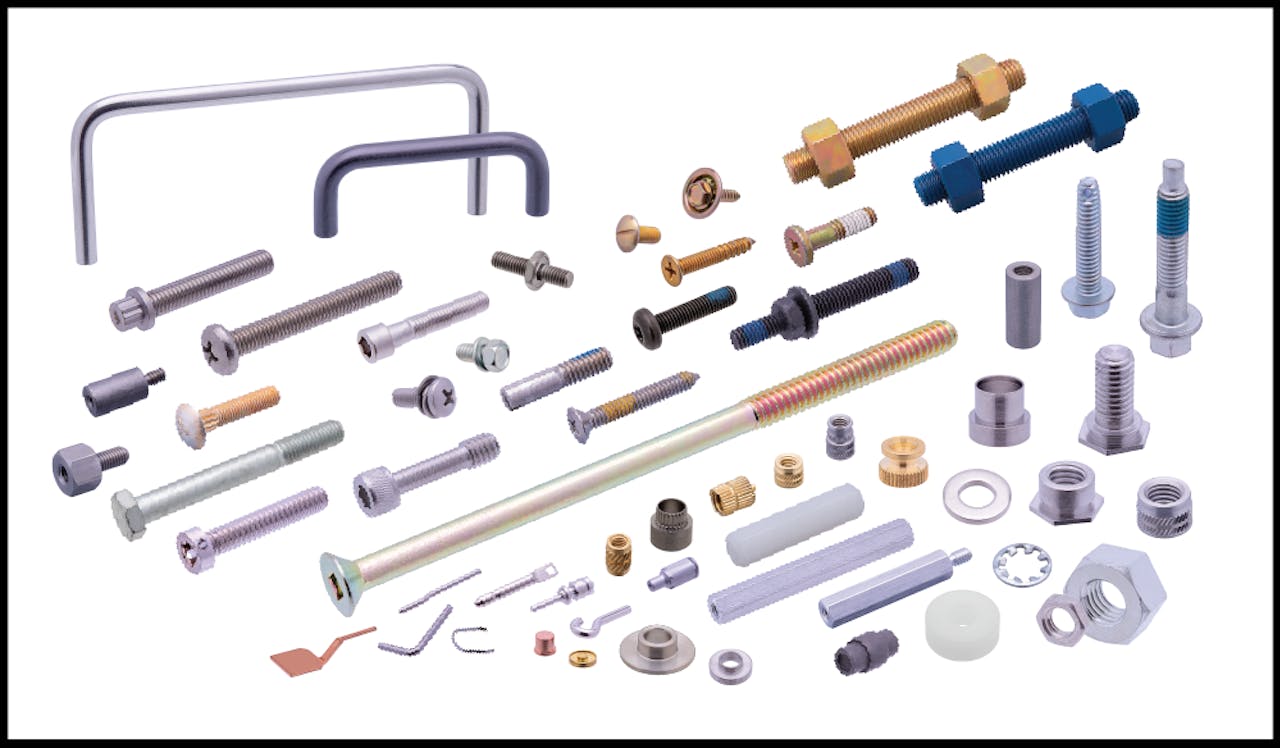

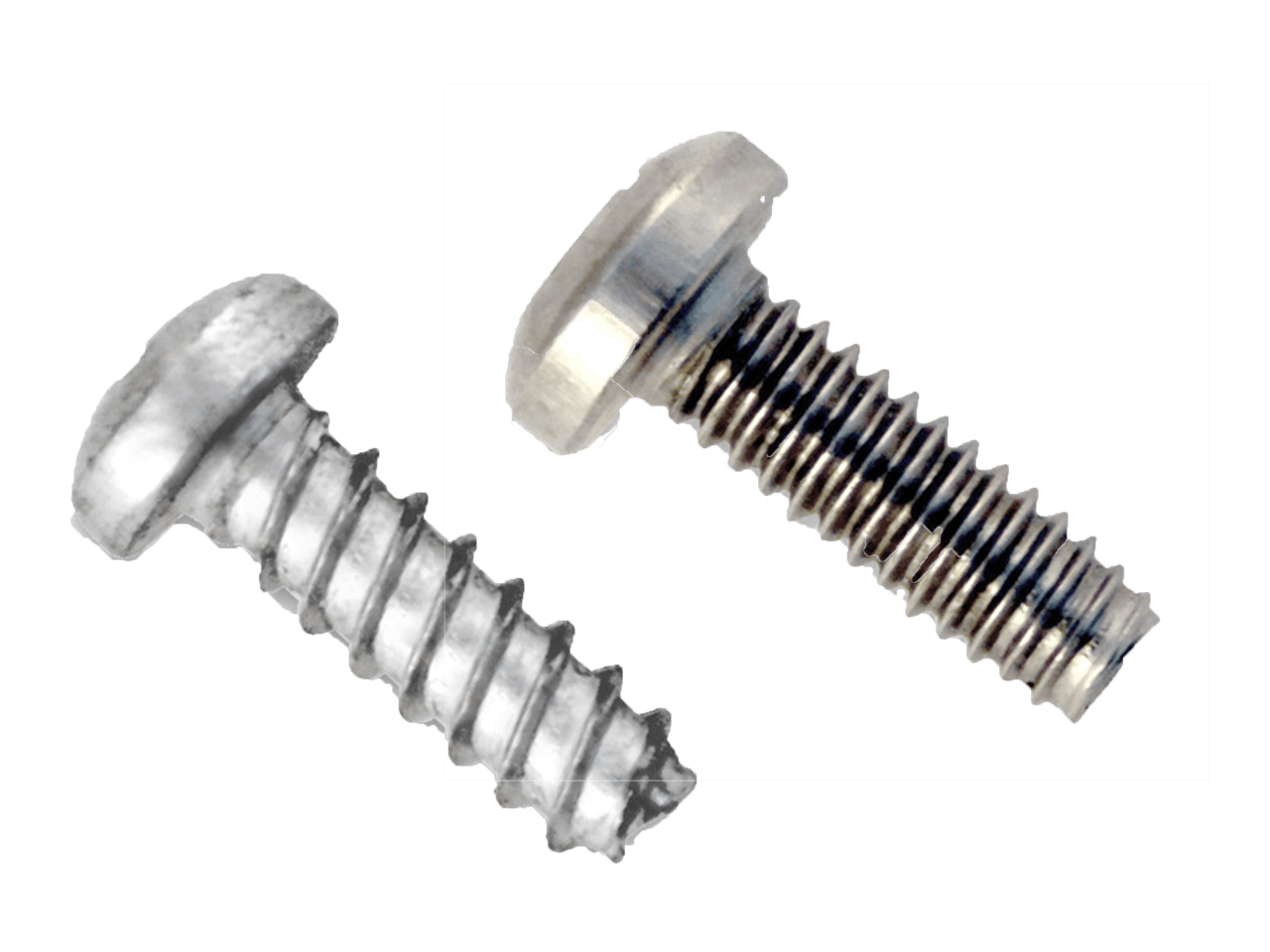

Cold Headed & Machined Fasteners

Get the mission-critical parts you need fast with same-day shipping on stock parts. Need something custom? We offer comprehensive solutions for precision machined and cold headed fasteners, from design optimization to production.

All Fasteners

Fastener Manufacturing

Our facilities have extensive expertise in design and manufacturing, including precision turning, close tolerance bending, critical application deburring, cleaning, and inspection. Our rapid prototyping service can help you quickly create and fine-tune your components prior to full production. And our design for manufacturability (DFM) know-how will help you develop higher-performing, more cost-effective parts.

View some of our design and manufacturing capabilities below or visit our manufacturing services page to see a complete list of the services we offer.

In-House Engineering Services for Specialty Fasteners

In-house tooling and CNC-controlled processes enable us to deliver parts to exacting tolerances, every time. We tightly control quality assurance using state-of-the-art inspection technology, enabling us to spot even the smallest imperfections. So you can be sure your fasteners will perform exactly as expected.

View some of our in-house engineering services below or visit our design and engineering services page to view all capabilities.

- CAD Modeling

- Rapid Prototyping

- Metallurgy

- Fatigue Testing

- Performance Analysis

- CAE Analysis

- 3D Printing

- Corrosion Analysis

Production Processes

From off-the-shelf fasteners to precision-formed fasteners designed for specific applications and everything in between. We have you covered.

View some of our common processes for fastener manufacturing below, or visit our manufacturing services page to view a complete list of capabilities.

- Cold Heading / Cold Forming

- Thread Rolling

- SEMS Rolling

- Head and Shank Slotting

- Trimming

- Heat Treatment

- Hardening

- Annealing

- Stress Relieving

Custom Fasteners / Specialty Fasteners

If your needs are unique, we can provide custom print-to-part manufacturing using our state-of-the-art equipment, which allows for the machining of specialty materials and tight tolerances to create precisely the specialty fastener you need. We even offer specialty thread patterns and configurations, including the patented MAThread® thread design. Fasteners produced with MAThread® threads are self-correcting and make damage and seizing impossible.

Are you just getting started with a project? We also offer specialized manufacturing of small, prototype quantities with a speedy turnaround time. Our specialty fastener locations even offer CAD-On-Demand to view and print your part anytime, anywhere with viewable 3D images and downloadable DXF, PROE, IGES, and STEP drawings of precision-machined fasteners and hardware.

Quality Certifications

When you partner with MW Components, you can be sure you’ll get the fasteners you need, to the quality you demand.

Our commitment to quality runs throughout our facilities which are accredited across multiple quality management systems. Some of our most commonly requested certifications are listed here, or you may visit the link below to view all available certifications we offer.

- ISO 9001

- AS9100D

- IATF 16949

- REACH Compliant

- RoHS Compliant

- DFARS Compliant

- API 14 A&D

Broad Industry Experience

MW Components has experience creating standard and precision custom fasteners for multiple applications and industries, including:

- Aerospace

- Agriculture

- Automotive

- Electronics

- Heavy Construction

- Energy, Oil, & Gas

- Heavy Truck & Bus

- Medical

- Defense

- Motorsports & Racing

- Power Tools

- Transportation

- Valves

- Semiconductor

Fastener Tools & Resources

Tools / Guides for Measuring & Buying

Case Studies

White Papers

Catalogs & Brochures

Questions about our fasteners?

Contact us. Our staff includes sales professionals who can help with pricing along with design engineers and manufacturing experts who can answer even the most difficult technical questions. Get in touch for questions about fasteners or any of our other products and we'll make sure you're connected with the person most qualified to help.

Blended Fastener Sourcing

Get high-volume, high-quality specialty fasteners—when you need them—with our global and domestic blended sourcing capabilities.

We can combine global and domestic sourcing to deliver high-volume fasteners with exceptional quality. We offer the price benefits of globally sourced items while filling demand spikes with domestic production.

Due to our quality control and shipping management, you can be assured of repeatable quality fasteners at competitive pricing. Our blending sourcing capabilities include:

- Global sourcing expertise

- Strong domestic production for demand spike response

- Quality control

- Logistics management

- Order priority

As the nation's largest single-source supplier of specialty fasteners, we deliver consistently high quality and a streamlined ordering process.

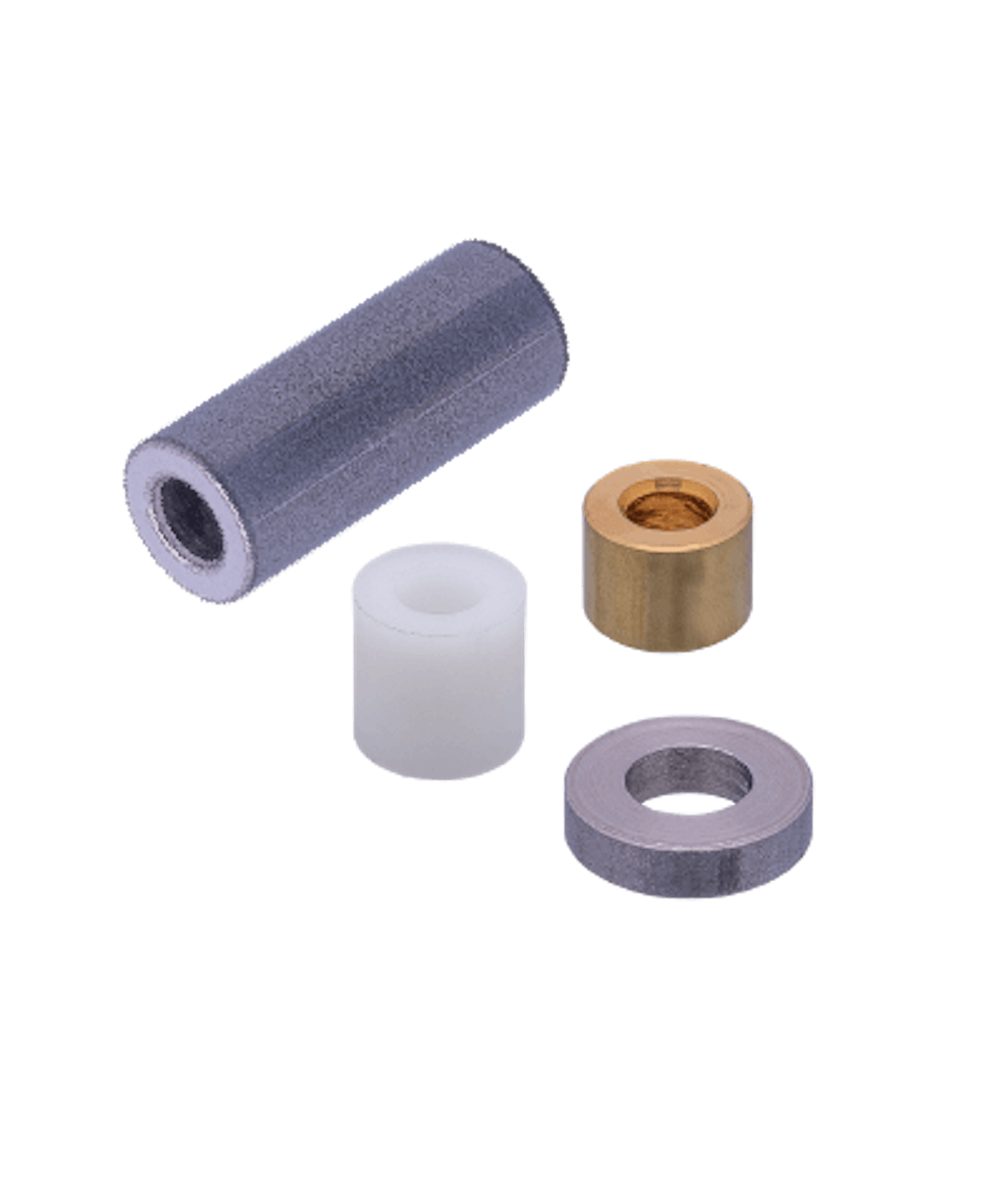

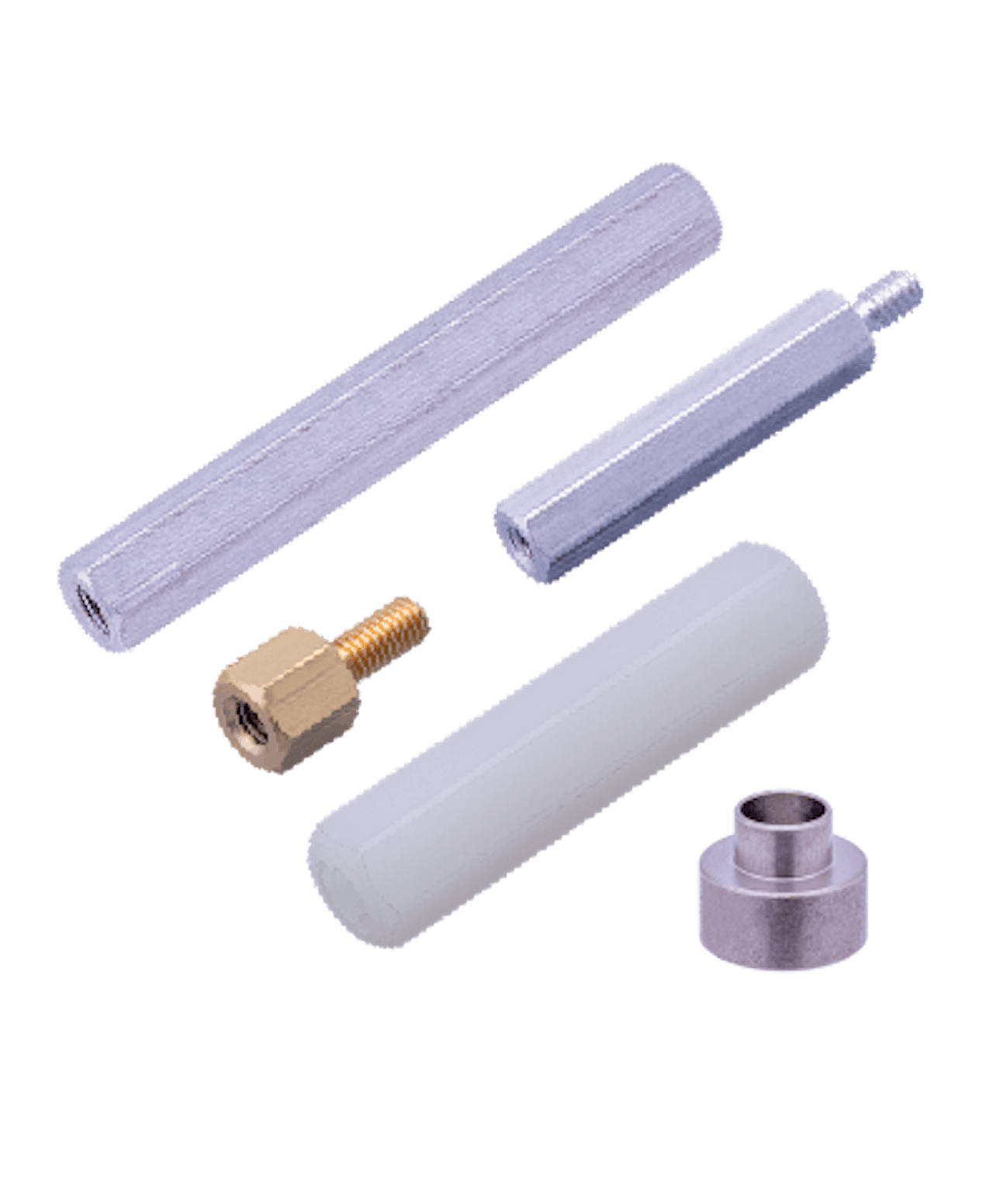

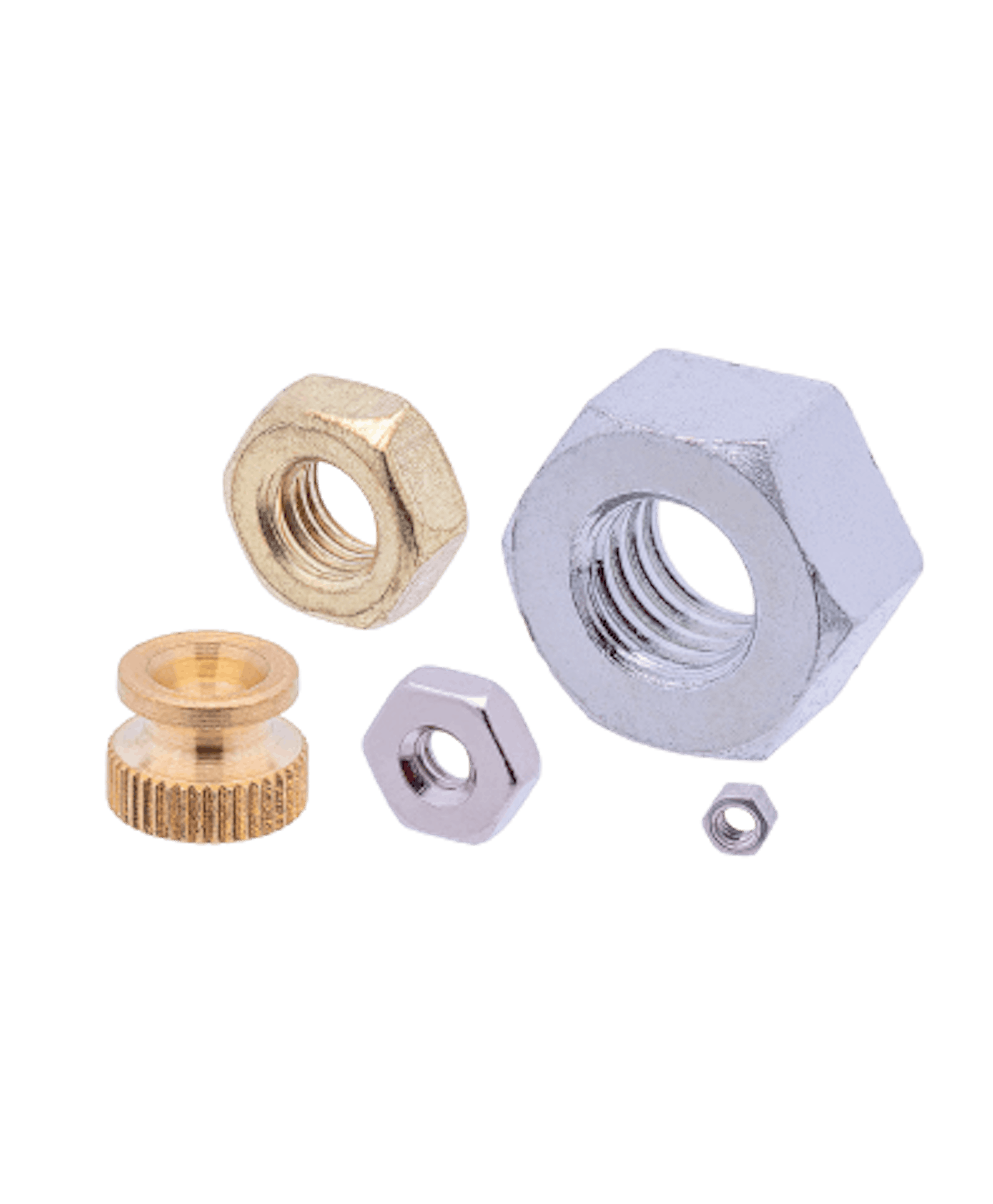

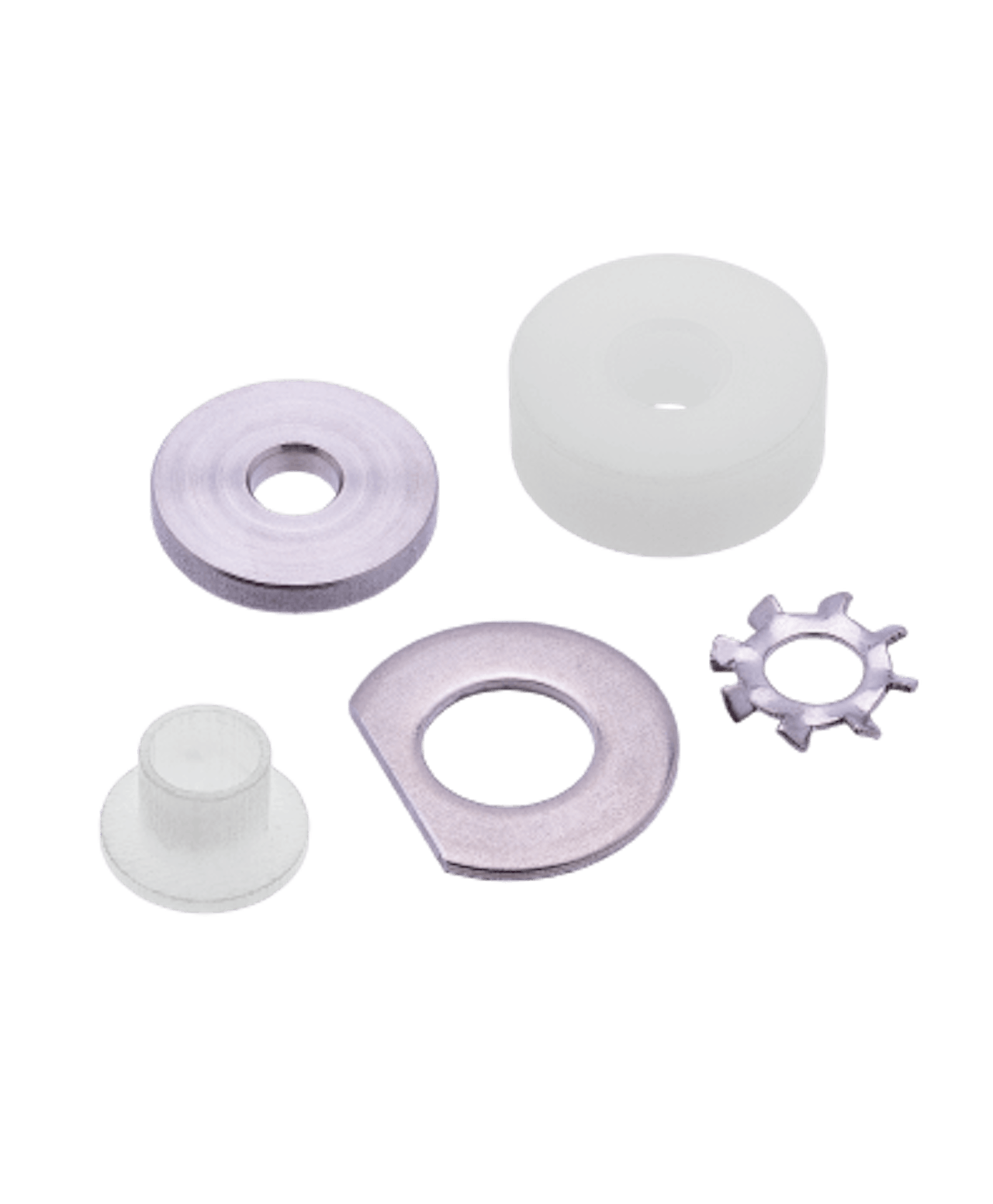

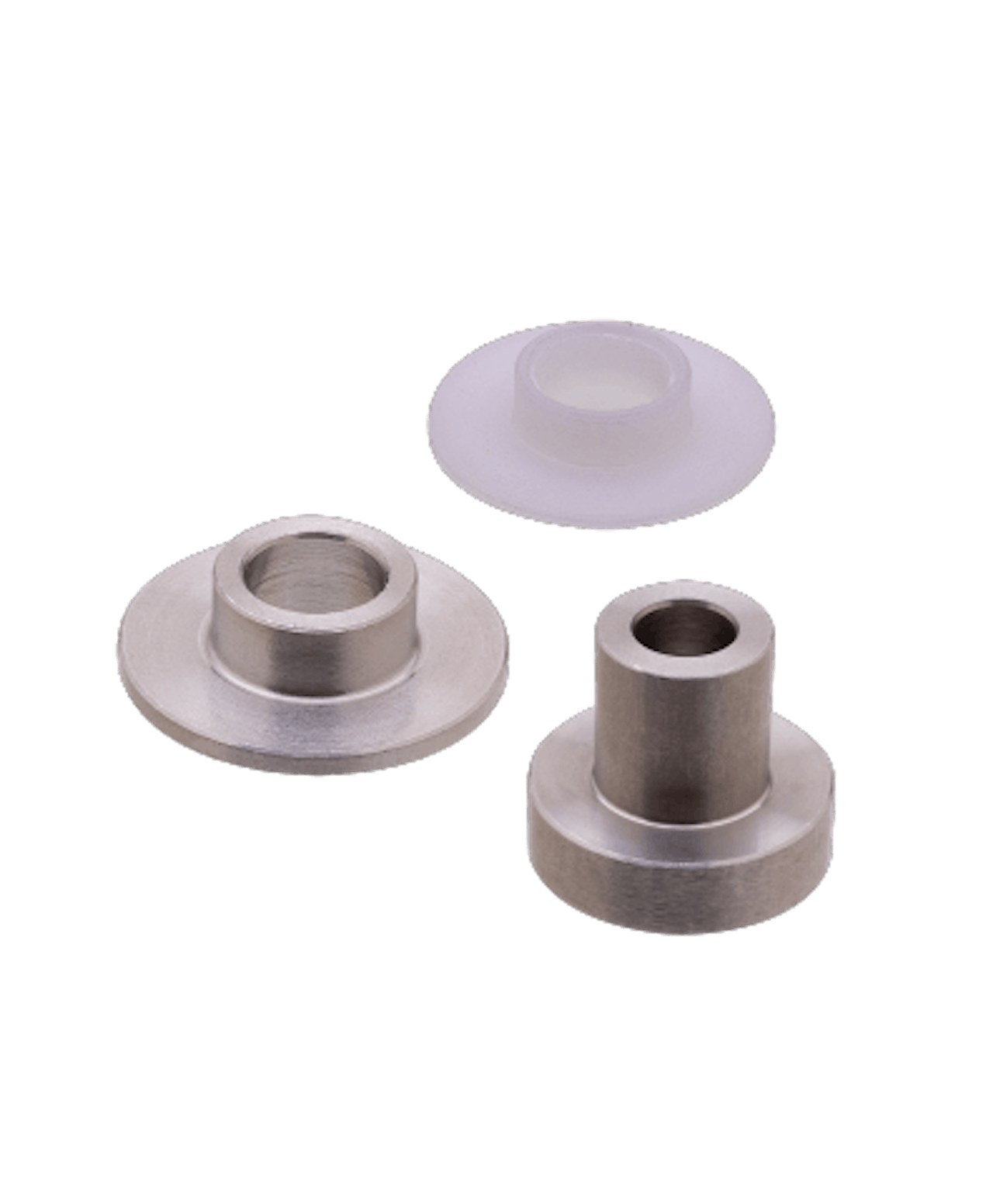

Precision-Engineered & Specialty Fasteners

MW Components offers one of the world’s largest ranges of precision-machined fasteners. We have over 45,000 standard parts in stock, ready to ship in under 24 hours. We offer industry-specific fasteners for specialized purposes such as National Aerospace Standard (NAS) fasteners and optional certifications such as API 14 A&D. And, when a standard part can’t deliver precisely what you need, we can custom manufacture fasteners to your exact specifications and typically ship within a week.

We’ll help you get the performance you demand with one of the world’s largest ranges of alloys and non-metallic materials—from beryllium copper, brass, steel, and aluminum to nylon, Teflon, and a range of specialty materials. And when you need more hands-on help, our 100+ engineers will work with you to develop and refine exactly the fastener to meet your specific requirements. Whatever your application, however tight your timelines, MW Components can help you get what you need, when you need it.